Expert Survey Solutions that deliver.

In industrial facilities where chemicals and nuclear materials are in use, precision, safety, and compliance are paramount. It isn’t just another accident in these locations; lives are at risk, and that means where additional precautions can be implemented, it is essential to do so. Chemical plants and nuclear facilities, with their intricate infrastructure and heightened […]

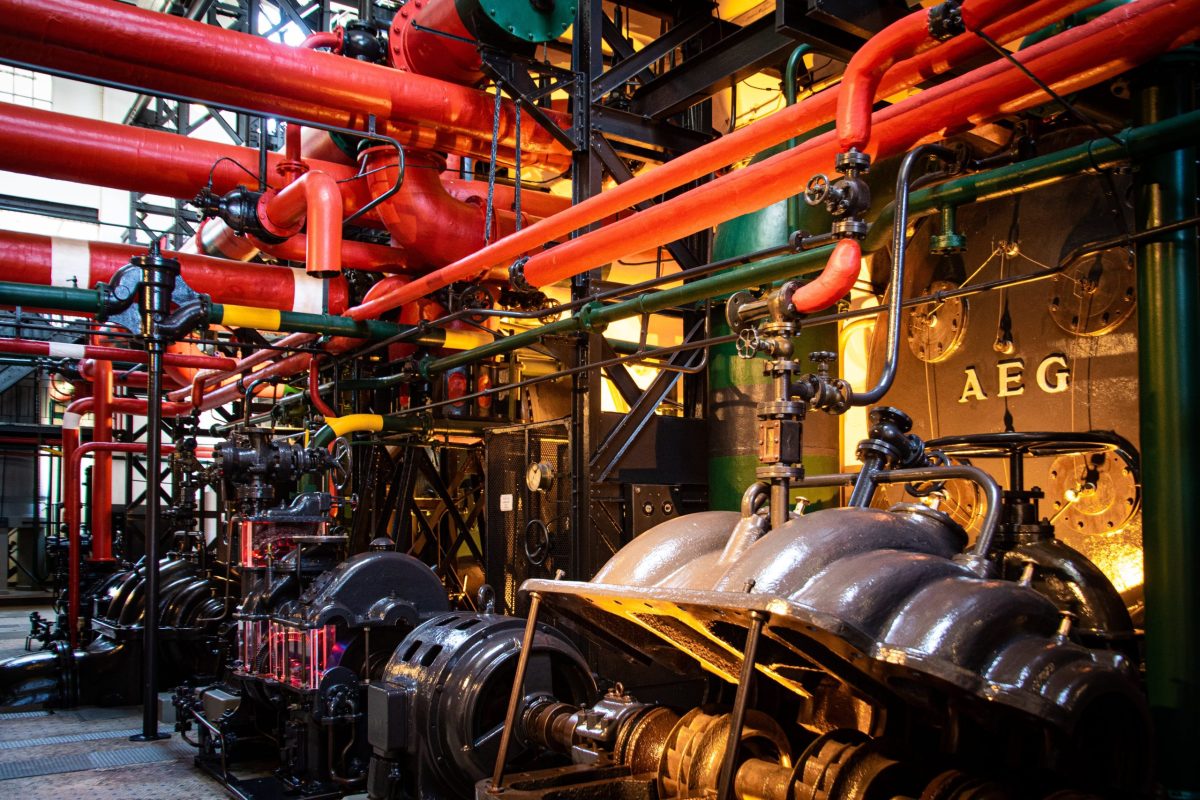

In industrial facilities where chemicals and nuclear materials are in use, precision, safety, and compliance are paramount. It isn’t just another accident in these locations; lives are at risk, and that means where additional precautions can be implemented, it is essential to do so. Chemical plants and nuclear facilities, with their intricate infrastructure and heightened safety concerns, have always presented a challenge, particularly when inspecting confined spaces and where exposure to hazardous materials may occur. These hard-to-reach areas are often fraught with risks, from toxic gases to structural instability, and sometimes it is impossible for humans to enter.

Innovative drone technology can transform these processes. Unmanned aerial vehicles, equipped with advanced sensors and cameras are transforming confined space inspections, in a far safer way. Not only are they safer, but they are more efficient, and can provide much more information, representing a cost-effective solution for chemical plants. Drones are reshaping the way we approach confined space inspections in chemical plants and nuclear facilities, and in this post, we’re looking at how drones can be used to make industrial facilities safer than ever.

Inspecting confined spaces in chemical and nuclear plants can be a complex and perilous task. These environments are usually built with tight quarters, limited accessibility, and often contain hazardous substances. Traditional inspection methods involving human entry pose significant risks to the safety of personnel, and take up substantial time and resources.

Navigating these confined spaces requires specialised training and equipment, and even then, risks remain high. The potential for exposure to toxic gases, structural instability, and the ever-present risk of accidents looms large. Because of these dangers, the need for innovative and safer inspection solutions, such as drone technology, is increasingly evident.

The use of drones can revolutionise confined space inspections in chemical and nuclear plants, since these versatile, unmanned aircraft can access tight, hazardous spaces that are difficult or dangerous for humans to enter. Equipped with high-resolution cameras, sensors, and in some cases, specialised tools, drones offer a unique vantage point for thorough inspections.

Their agility, speed, and ability to navigate confined spaces with ease make them a cost-effective and efficient alternative to putting humans in danger. By reducing the need for human entry into hazardous environments, drones prioritise safety while delivering valuable data that can inform critical decisions. With ongoing advancements in drone technology, their role in confined space inspections is set to grow, marking a promising future for industrial safety and efficiency.

Drones can be used for many different applications in chemical and nuclear plants, but most importantly, for inspections and maintenance processes. They can be employed for various critical tasks, including corrosion detection, leak identification, and structural integrity assessments. In chemical plants, drones navigate through intricate piping systems to spot corrosion or potential leaks swiftly. In nuclear facilities, they can be used to assess radiation levels and inspect hard-to-reach areas without human exposure.

In addition to emergency repairs, drones can aid in routine facility checks, monitor equipment performance, and provide a bird’s-eye view of vast areas. Their ability to collect high-quality data efficiently ensures that safety and operational standards are upheld in these sensitive environments, reducing risks and enhancing overall plant efficiency.

As we’ve discussed, drone technology has emerged as a beacon of innovation, offering a safer, more efficient, and cost-effective alternative to traditional methods. The advantages are clear: heightened safety for workers, reduced downtime, enhanced compliance, and access to valuable data that can drive smarter decisions.

The Elios drone is specifically designed for inspections in confined spaces, and the small size, manoeuvrability, and safety features make it well-suited for this task. With high-resolution visual and thermal cameras, we can capture detailed images and data during routine, and emergency inspections.

The data we capture can identify potential hazards like structural weaknesses or leaks, and is ideal for planning maintenance and repairs. During the flight, the live video feed from the drone’s camera allows real-time monitoring, and we can adjust the flight plan as needed. After completing the flight, the captured data and images are used to generate detailed reports that pinpoint any issues requiring attention.

At Angell Surveys, we understand the power of innovation, and we’re ready to help make your chemical or nuclear facility safer, more efficiently than ever. To discuss your needs, get in touch. Not only will your inspections be safer, smarter, and with more information than ever, but we provide warranties to back our actionable data, and our fleet of drones means we can service any size of project.

Trust Angell Surveys for cutting-edge technology, expertise and timely delivery when it matters.